-

Posts

7,516 -

Joined

-

Last visited

-

Days Won

174

Content Type

Profiles

Forums

Events

Posts posted by comp56

-

-

truth be told if this was 20 years ago I would open up a shop and go crazy but not now I build tables at my own pace and usually for family and friends and in some cases myself......(our poker room has 2 full size tables at all times) this is just a pass time alternative to sitting on the front porch carving wooden arseholes for hobby horses.......

-

ya the cleaning tip is only going to give more cuts or prolong the inevitable of resharpening or replacing the tool bit or blade......

-

not to be critical but when cutting wood the dual saw would be creating more saw dust........

-

thanks all, Ive had my chuck key on a steel version of one of these for years hanging on the side of my drill press.....it is just long enough to use and swings back into place.........you could just use a cable or a string but this way it is never in the way.....

-

if you want more life from your blade, take it off every once and awhile and soak it in vinegar over night .......you wouldn't believe how much better it cuts.....I do the same with router bits as well......eats the residue from the cutters that builds up and hardens.....

or if your in a hurry take blade off spay oven cleaner (easy off) on it both sides, go for lunch and wipe off, keep cutting.....

learnt that trick years ago from a blade shop, a lot of blades that came in for sharpening only needed cleaning.......

-

just a quick little tip.........

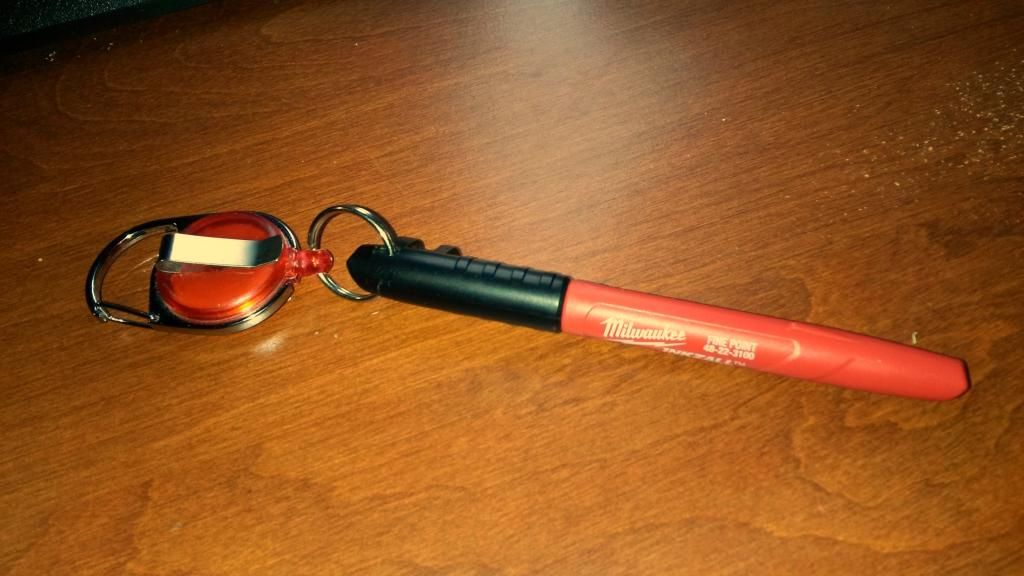

Some tools you carry around with you and are needed all over the place but for me usually when they are small they are left where I used it last. So in my shop I put together a few of these for each station if you will, band saw, drill press, mitre saw ect ect

I noticed the lid fits pretty snug with a good click so I took a spring loaded belt clip thingy and with a key ring connected it to the lid of a Milwaukee inkzall and hung it off each tool....

I'd say just hang it off you belt and you would have it always but I personally rather not.....

-

5

5

-

-

part of me does and part of me don't, funny thing is I miss the noise the most .....nothing better sounding than a busy shop.....

-

-

ya the price of some stuff is crazy, but I guess they play on the fact some people can't or don't know how to build stuff......

-

Get me some broader pics of it and some general info on the build and I'll put it on the main page

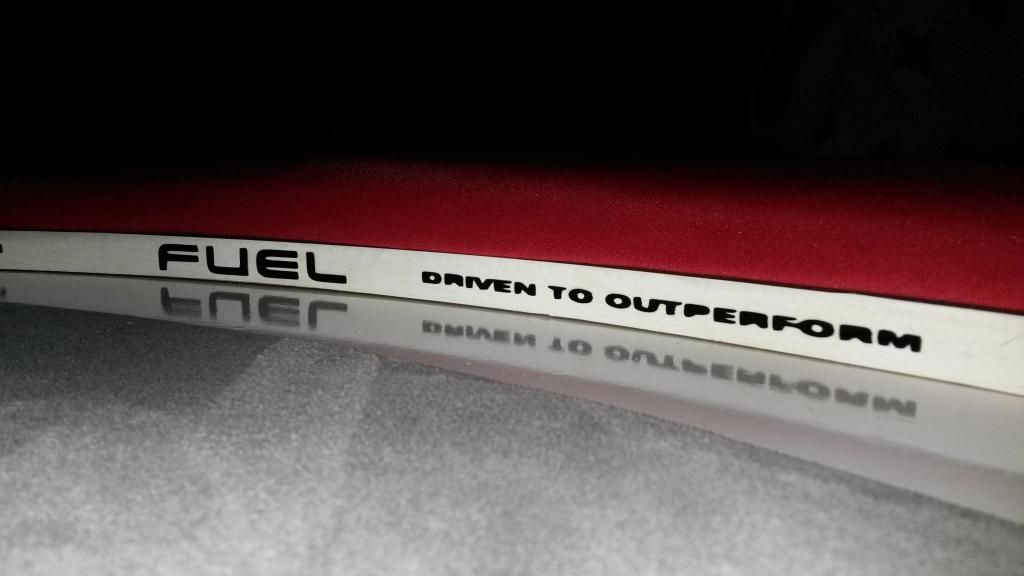

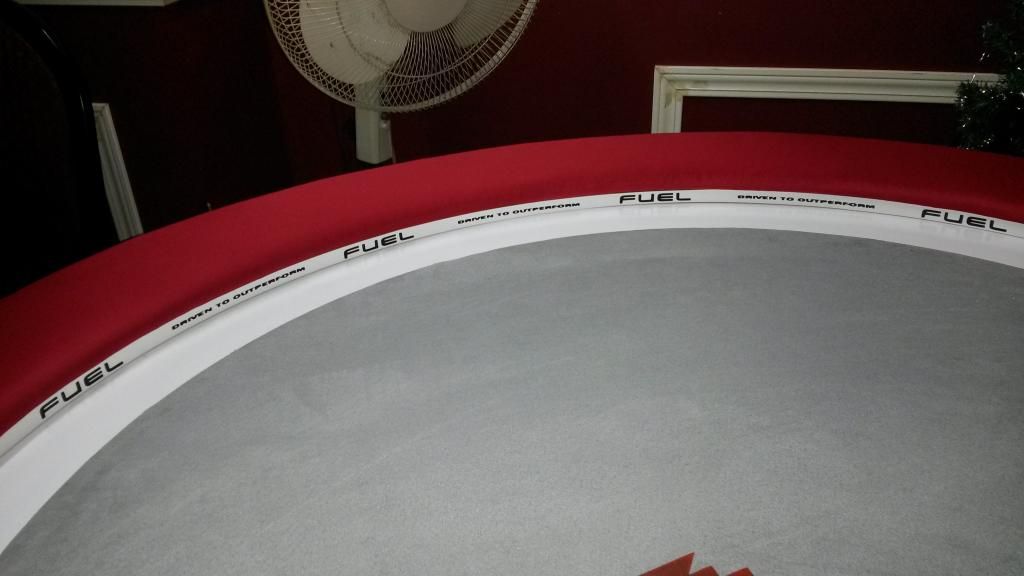

The Milwaukee Poker Table is a full 60" round table with a seamless 6" raised padded rail with 105LBS high density foam,

3" rubbed white lacquer finished racetrack with 4 coats of poly for harness,

play area is mounted flush to racetrack and is also padded with 1/4" high density foam, the ply area is water and stain resistant gaming suede with dye sub printed logo of Milwaukee of course....

Table is mounted to extra wide folding legs

table can fit 8 players comfortably and a 9th if needed..........

-

2

2

-

-

during high school worked at a local machine shop part time until I finished school, then they offered me an apprenticeship and became an interprovincial machinist after a few years the shop offered me more training and became a fabrication engineer until I retired, worked for the same company my entire career ......

-

4

4

-

-

I can't go without my stand and I love the fact it has wheels as well.......total bonus....

-

-

if your using a kreg pocket screw set up ya probably don't need to glue it however if you still want to I suggest gorilla wood glue.....MDF usually don't like glue because it is very porous but you should be ok for a book shelf.......apply a very thin coat on both sides of connection and let sit 10 or so minutes then apply again just before you screw it tight wipe off any extra....

-

1

1

-

-

-

January? furnace is on at night already here .....and I'm sick of it...lol

-

I got a request for a few 60" round tables all with 6" raised suede rail, small 3" race track and gaming felt, folding legs....Table you see here shows larger rail 1 piece no seamstable is ready for center to be cut out and gaming felt to be added flush....rail looks black but it is dark brown in person.......Got a couple other colour versions as well with the following grey rail with lighter grey play surface another with real dark brown almost black rail with lighter brown gaming suedeI will post the detailed build of these 60" round tables if there is any interest....

-

-

-

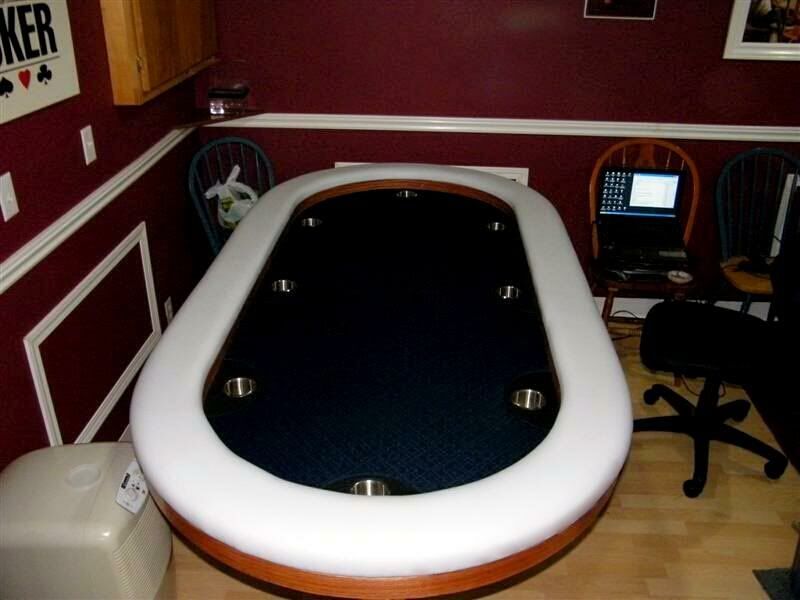

I figured I would post the hobby I took up since my retirement from being a fabrication engineer a few years back......I build Poker tables as a hobby and not a business.....(work at my own pace)anyway here are a few builds that stand out from the tables that have gone through my little workshop.....well over 50+here is a full size oval table with hide-away cup holders, you can have a cup holder in front of you or simply spin the disc and it is hidden under the rail....a quick shot of the mechanics of the table....

-

wife and I both drive new vehicles with warranty and or road side assistance if there is a problem I make a call........I paid way to much to get my hands dirty........

-

1

1

-

-

A DIYer or homeowner can get away with only one, since they can have the time to come back and finish after it recharges.

I'm self employed (wife calls it Semi retired) and most of all my work is done from home, however when I'm doing something for the house/family/wife there is nothing worse than being in the middle of a job and having to wait......some times jobs can only get done at certain times of a day...

I suggest a 2 battery minimum for a diyer

-

ya just glued and screwed.........built one about 15 yrs ago for a sister looks pretty much same as then

-

The few times I have sold tools because I got a bigger better faster version or got some new as gifts most if not all are given/sold cheap to a buddy or traded. I have lots of tools that have been kickin around for 25+ years still work like the day I got them.......in fact I even have some older stuff my father passed on to me.....may not look as good as the new stuff but in some cases are way better......some tools wear out and some last forever......just like anything else the old saying they don't make em like they used too........some times it has a lot to do with how they are treated/used...I know some guys go through tools like socks and it's usually cause they don't know what they are doing or don't care......then they say oh such and such are garbage??? yet mine is 8 yrs old and works perfectly......

.jpg.a8ace1e1e5f4a7fbeda366b4de36c9a6.thumb.jpg.7b9a9aa4548d9fe684006b6f59de8424.jpg)

Titanium Dioxide Batteries, The Future is ...coming within 2 years.

in Power Tools

Posted

we need carbicells, 1" square on top of everything that needs electrical power that is charged from the ambient light like solar panels...I know it is a stretch but so was remote start on cars 30 years ago.........