-

Posts

2,563 -

Joined

-

Last visited

-

Days Won

17

Content Type

Profiles

Forums

Events

Posts posted by Stercorarius

-

-

"If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock."

Sent from my iPad using Tapatalk

Yeah, the GFCI that Hilti builds into their cords did the same thing. It really saved me on that one because it was plugged into a welder with probably nonexistant circuit breakers.

-

A lot of people hate pegboard, but I've found that it promotes much better organization, and minimizes the brutality of the humid southern summer. I keep the essentials on my pegboard, and everything else in the toolbox.

Ill find a pic of it for you

At work the shop is completely sheated with pegboard up to 8' high (20' or higher steel building) and it holds every tool. I'm surprised at some of the stuff it can hold like 1" drive impact guns.

-

Ancient Chinese secret.

Owner is on another forum with a thread about it.

Sent from my XT1254 using Tapatalk

Fair enough.

-

56 minutes ago, comp56 said:

go to scrap yard rip out sound deadener from under carpets of cars double it up if need be cheap cheap works good too....

Also a great idea, the only times this is is a problem us when you want the dense stuff because it is almost always adhered to the metal. The other problem you encounter is when the nearest scrap yard is over two hours away

.

.

-

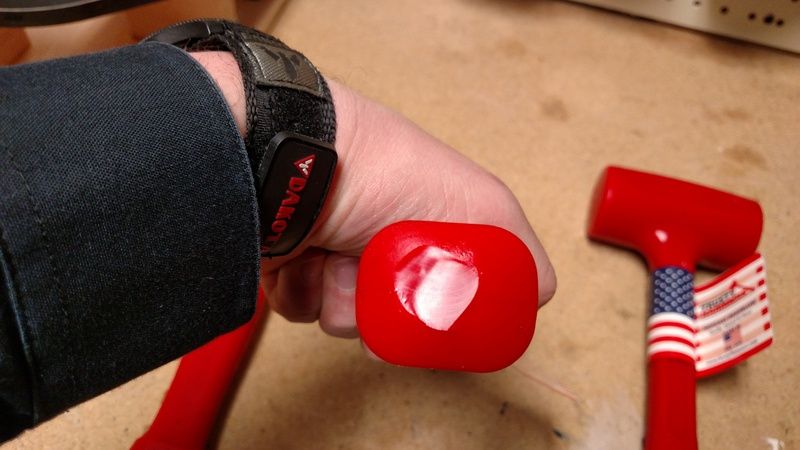

$37 for all three plus shipping. Half off because of them being blemishes.

Sent from my XT1254 using Tapatalk

Where'd you manage to get them from?

-

Looks like linoleum to me.

-

4 hours ago, mohawkdec said:

couple of items came today. im hoping to compare the dewalt to my brothers bosch 360 which i feel is the king, at the moment, im going to use my ipod which has nothing but full cd quality tracks on it, no mp3 crap, being the old hippie i am i like my music clear and loud. the other item is high on my list for work items, and its a good pair of work pants. every since carhartt decided to leave us, i started to check out european style clothing, ive had mascot brand for almost two years now, and havnt broke them yet, this is my first pair of blaklader. i got 3 pairs of carhartt this past xmass, 2 are in the repair pile, one with a left blown out left knee, and the other the rear pocket decided to leave my ass and rip off

I can't say anything about the Bosch, but that radio has no problems putting the Milwaukee to shame.

-

1

1

-

-

-

Nice little tool. I feel cleaner cuts would be achieved with something different though

All the drywall crews I've dealt with and my dad run rotozips (name brand version of this) for doing drywall. It kinda leaves a roughish edge, but everything else does too. Not a big deal once the covers go on. You won't see these being used to cut sheets, that'll always be done with a utility knife and big T-square.

-

2

2

-

-

Geez freshman year I figured out how to install pacman and Tetris on my TI-84. All I gotta say is, Most productive math class ever. I got to like level 14 on Tetris. I don't know how to graph an inverse trig function, but I know an opportunity to clear four lines at once when I see one.

-

3

3

-

-

Thanks for the bump KnarlyCarl. Somehow of the other this post had eluded me. I gotta say I live your tools fazzman. Do you do any kind of engine machining? You could do some serious motor builds with all those tools. Wouldn't have to dick around with plastigauge at least.

-

1

1

-

-

I love hilti tools. The only issue I ever had with a hilti was a core drill. Like this one.

It was a rental so I'm sure it had had more than its fair share of abuse. I was drilling out drains for some water troughs with another guy because you're best of trading out when you're drilling horizontally at ground level through an 8" wall with a dull bit. A hose wasn't an option due to the location and missing hookup on the drill so one guy had a bucket of water. So basically we were kneelin on concrete in about two inches of water and cow shit drilling all day. Point is we were well grounded. Before you jump to conclusions these drill are designed for wet environments and I've used them while laying down in trenches with standing water in them with no problems an the cord was out of the water plenty. Anyway the other guy was drilling and stopped suddenly and said he thinks it shocked him a little. I was 16 or 17 and cocky and it was his first week on the job so I just thought he was being a b***. I traded him out and started drilling and every now and then I'd have a short pulse of electricity shock me and I'd keep going while he laughed because it wasn't that bad and we just wanted to be done. After about the tenth or so time it finally unleashed Zues's full fury on me and shocked you as bad as 120v can. Friggin hands clenched up and my muscles in my forearms went all haywire for a good two seconds and then it stopped when the GFCI on the cord tripped. We reset GFCI on the plug, I insulated myself and pulled the trigger, the drill wouldn't even start to turn anymore. It was completely fried. The Hilti color still makes my hands twitch when I see it. Moral of the story: AC and water doesn't mix, ever. I've got some other stories about being an idiot with an AC stick welder and standing on an aluminum ladder, or working on live pump controllers that I'll spare you from having to read.

-

7 hours ago, PROTOOLNUT said:

Hey, I got a TIA sticker on my air compressor too! I like your Huskey, silant flow ha, but looks like its in a box anyways hehe. Well, my air compressor is louder then most people's compressors, so its easy to see why I want to build a box for it. The only problem with building a box for an air compressor, is you need to allow holes for airflow, so like one hole for the intake, and one hole for the fan that keeps the unit cool. You also need to allow a hole for your air line, and a hole for the drain. I hear that sound proofing material can make the sound even quieter but I've been told the stuff is expensive. Ya, imagine that, foam being expensive lol!

As far as sound deadening goes, I'll teach you guys a trick that is only known among a select few guys like myself who run around in rice burners and some hicks. If you are looking for an expensive sound deadening liner, Dynamat is the name to know, but if you're a schmuck like the rest of us and want a cheap effective alternative, run down to Lowes and grab yourself some peal-n-seal self adhering flashing from the roofing aisle. It works well as sound deadening for sheet metal at low cost. This has been used with varying levels of success on a few of my vehicles. Sorry for the hijack.

-

Sent from my SCH-I545 using Tapatalk

Where'd you get those steel mesh crate/pallets from? I've only seen those come from irrigation companies. They're nice for scrap metal.

-

Never used suspenders, just because my dad never does and he was the one who taught me.

-

I love this Gun, and the Collated attachment is second to none...

What is up with those people and saying literally all the time?

-

3000 in-lbs or ft-pounds?

-

Yeah it looks like the k isn't silent. On the videos where the Germans say it it is literally pronounced knipex. There is almost no "uh" to the "kuhnipex". I'm guessing the founder just called it what the sound effect of his pliers cutting something sounded like.

-

Whats that?

It's an elusive concept, some day I have it figured out and some days it has given up and ran off, leaving me alone standing with an open wallet at the tool store like a fool. It seems to me that I only have self control visit me after buying a proto pipe wrench that I really can't afford.

-

2

2

-

-

Yea thats typically the way to do it unless your adding, I add boxes for home theater work from time to time so this concerns me a little...

Do you just run with a jab saw right now?

-

Never mind, it is the kit. I'll have to pass for now, seems to gimmicky to be a reliable concept. Let me know if I'm wrong.

-

Is this the bare tool or nah?

-

Neat

-

Nice vid. I love that gun. I had the same problem with slamming them sideways too at first. I would love to try the collated attachment because I drop screws like no other when I do ceilings. I leave it spinning almost always. The runtime on that thing is enough that your other 2.0 will be charged well before your current one dies.

Godda Love the Weather......

in Pub Talk

Posted

This winter was horsecrap. It was really warm for a winter, it dropped to the single digits for only a week instead of the usual month. And it was wet. I thought I was supposed to be in the dang desert but we've got some kinda rain almost once a week this year. It's never had this much moisture in my life. The worst part is that it hovered right around 35 degrees all winter so nothing froze and nothing dried so everything became several feet of mud everywhere for the whole winter. Hey at least there's the off chance that we don't have another drought this year and the even more unlikely chance that the entire East half of Washington isn't covered in wildfires all summer. Lost too many firefighters and houses last year.